If you are searching for a Gas sensor module with a very High detection range compared to any ordinary gas sensor then this MQ-2 Smoke LPG Butane Hydrogen Gas Sensor Detector Module will fulfill your specification demands. The MQ-2 Flammable Gas And Gas sensor detector module has a detection range of 300-10000 ppm. The gas sensor modules are always well known for their robust and simple construction and measures toxic gases in very low concentrations.

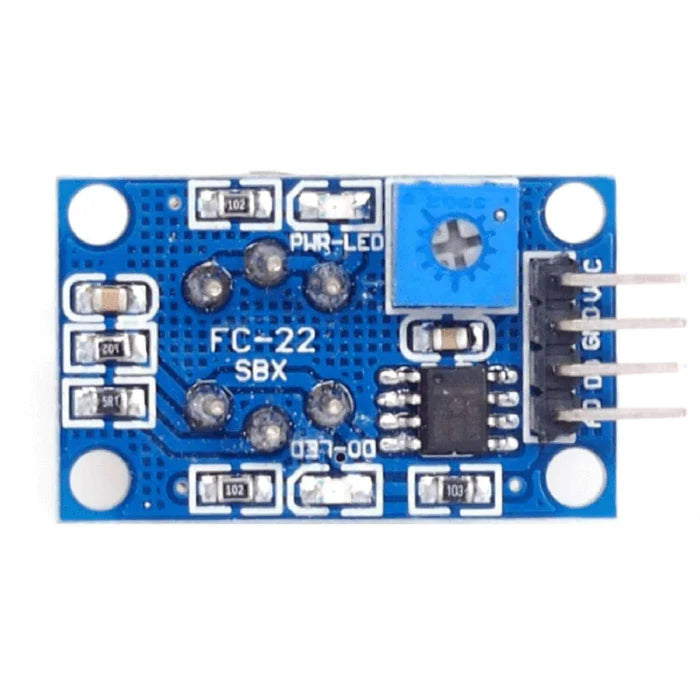

The MQ-2 Smoke LPG Butane Hydrogen Gas Sensor Detector Module is useful for gas leakage detection (home and industry). It is suitable for detecting H2, LPG, CH4, CO, Alcohol, Smoke, or Propane. Due to its high sensitivity and fast response time, measurements can be taken as soon as possible. The sensitivity of the sensor can be adjusted by the potentiometer.

MQ-2 gas sensor using gas sensitive material is to be clean air in the lower conductivity of stannic Oxide or tin oxide (SnO2). When the sensor when flammable gases are present in the environment in which the conductivity of the sensor with an increasing concentration of combustible gas in the air increases.

Use a simple circuit to convert the changes in conductivity and output signal that corresponds to the concentration of the gas.

MQ-2 gas sensor higher sensitivity to liquefied petroleum gas, propane, hydrogen, detection of gas, and other combustible vapors are ideal. This sensor can detect a variety of flammable gas, is a low-cost sensor for many applications.

Following conditions must be avoided

Water Condensation

Indoor conditions, slight water condensation will affect sensors’ performance lightly. However, if water condensation on sensors surface and keep a certain period, sensor’ sensitivity will be decreased.

Used in high gas concentration

No matter the sensor is electrified or not if a long time is placed in high gas concentration it will affect the sensor’s characteristics.

Longtime storage

The sensor’s resistance produces reversible drift if it’s stored for a long time without electrifying, this drift is related to storage conditions. Sensors should be stored in airproof without silicone gel bag with clean air. For the sensors with long time storage but no electrify, they need a long aging time for stability before using.

Longtime exposed to an adverse environment

No matter the sensors are electrified or not, if exposed to an adverse environment for a long time, such as high humidity, high temperature, or high pollution, etc, it will affect the performance of the sensor badly.

Vibration

Continual vibration will result in sensors’ down-lead response then rapture. In transportation or assembling lines, a pneumatic screwdriver/ultrasonic welding machine can lead to this vibration.

Concussion

If sensors meet strong concussion, it may lead its lead wire disconnected.

*Note: Product Image are shown for illustrative purposes only and may different from the actual product.